Leave a Message

We will call you back soon!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters!

Please check your E-mail!

Please check your E-mail!

Please check the verification code!

Please check the verification code!

SUBMIT

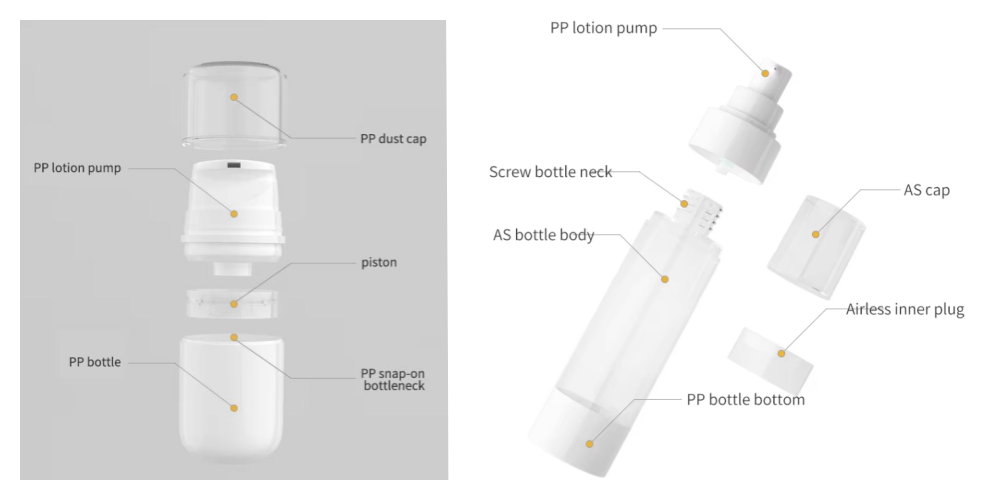

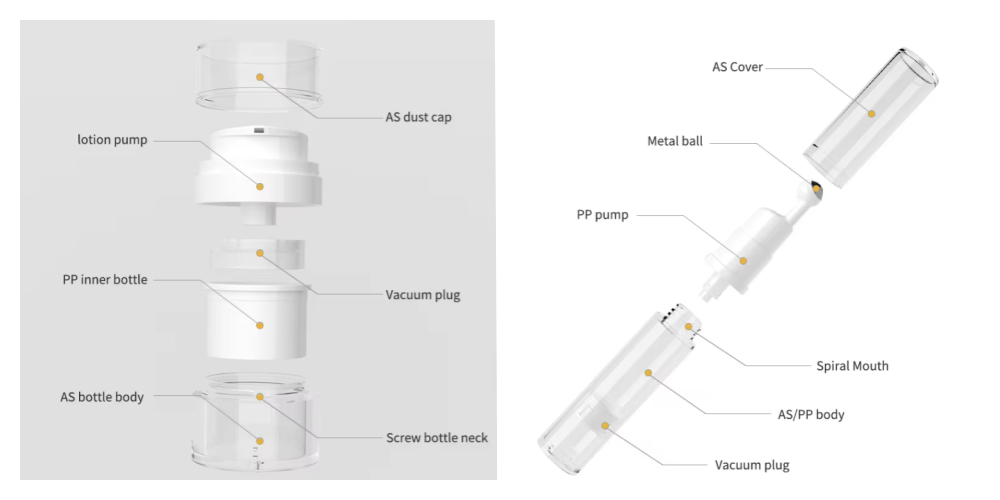

Overall Composition

A plastic vacuum emulsion bottle generally consists of a vacuum bottle body, a pump head assembly, a piston, and other parts. Each part undertakes different functions to realize the storage and dispensing of the emulsion.

Details of Each Part's Structure

Vacuum Bottle Body

Material Chamber: Located inside the vacuum bottle, it is usually a straight chamber with a smooth inner wall, designed to store the emulsion. For example, in some designs, such a material chamber is set below the fixed cap inside the bottle.

Vent Hole: Positioned at the bottom of the vacuum bottle, it connects the inside and outside of the bottle. Its function is to balance the air pressure between the inside and outside of the bottle, enabling the material - pushing piston to move up and down smoothly.

Material - Pushing Piston: Placed in the material chamber, it fits well with the inner wall of the chamber and can move up and down. When the emulsion is pumped out, outside air enters the bottle through the vent hole. Under the action of air pressure, the material - pushing piston is pushed upward, continuously pushing the emulsion towards the pump head. In some designs, the inner side of the outer edge at the top of the material - pushing piston is equipped with a sunken groove, and a downward - concave material - collecting groove is set in the middle of the sunken groove, which helps to make more full use of the emulsion in the bottle.

Pump Head Assembly

Fixed Cap: Fixed at the bottle mouth of the airless bottle, it seals the bottle opening. Meanwhile, a pump chamber is set on the fixed cap, which is the key passage for the emulsion to be pumped out. The lower end of the fixed cap may be equipped with a downward - protruding insertion column, on which a feed hole and a one - way valve are provided.

Pump Chamber: The feed hole at the lower end of the pump chamber is connected to the vacuum bottle and is equipped with a one - way valve that only allows the contents in the vacuum bottle to enter the pump chamber. This ensures that the emulsion can only flow from the bottle into the pump chamber, preventing the backflow of the emulsion. Inside the pump chamber, there are an upper pump rod, a lower pump rod, and a pumping piston.

Upper and Lower Pump Rods: The upper end of the upper pump rod extends above the pump chamber and is equipped with a press head for easy pressing operation by users. The lower end of the upper pump rod is connected to the lower pump rod. When the press head is pressed, the upper and lower pump rods move downward, squeezing the emulsion out of the pump chamber.

Pumping Piston: It is sleeved between the upper and lower pump rods and plays a role in sealing and pushing the emulsion in the pump chamber. A locking cap is fixed at the upper port of the pump chamber to prevent the pumping piston from coming out of the pump chamber.

Locking Cap: It has an upward - facing lower conical part, which cooperates with the downward - facing upper conical part at the upper end of the upper pump rod. A plastic tube is sleeved on the outer side of the upper pump rod, and the plastic tube is pressed between the upper and lower conical parts. The plastic tube is provided with a break seam, allowing it to elastically expand or contract the tube hole horizontally. When the press head is pressed, the plastic tube expands the tube hole to allow the upper pump rod to move downward; when the press head is released, the plastic tube contracts itself to push the upper pump rod upward.

Press Head: The part at the upper end of the upper pump rod. A plug cap may be inserted at the nozzle of the press head, and the plug cap is equipped with a handle, which is convenient for users to pinch with their fingers to remove the plug cap from the nozzle of the press head.

Other Parts

Cover: It is connected to the vacuum bottle and is used to cover the press head inside. It protects the press head and prevents the accidental extrusion of the emulsion.

Plastic vacuum bottles and airless jars are not only applicable to cosmetics but also widely used in the liquid packaging of the pharmaceutical industry, as well as in daily chemicals, hygiene, and food sectors.